Meshstore New Zealand stocks the highest quality expanded mesh products available in New Zealand. You can be sure that every effort has been made to produce mesh that closely matches the quoted measurements, every single time. However, as with any manufactured product, some small variations will occur between individual sheets or between different batches and this is completely normal. As long as these variations fall within acceptable limits, known as tolerances, then the mesh is ‘in spec’ (meets specifications) and is fit for sale as A-grade product.

This article describes the dimensions and other properties of expanded mesh that are subject to manufacturing tolerances, and what the allowable values are for each.

You might also like to check out our What is Expanded Metal and Expanded Metal Glossary articles.

Understanding Tolerances

When buying expanded metal mesh it’s helpful to understand the tolerances, because even a small variation can sometimes impact you in real life if they haven’t been considered. A good strategy is often to design your project with an allowance for any small differences that might exist. Or alternatively, planning in advance to trim each sheet to final size and shape if high precision is essential to your job.

Also bear in mind that product specifications (and tolerances) may be subject to change over time as manufacturing machinery and practices evolve.

Length and Width

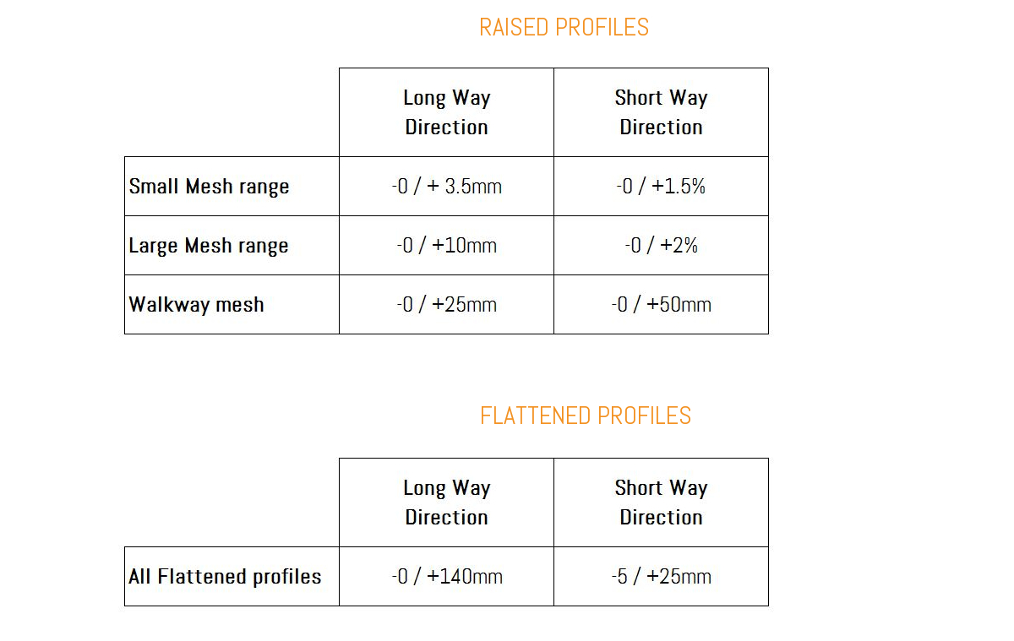

All product dimensions quoted for expanded mesh should be considered ‘nominal’. The following tables show the tolerances on the expanded metal sheet sizes:

Note: Drawings in the following sections have been exaggerated to illustrate the concepts

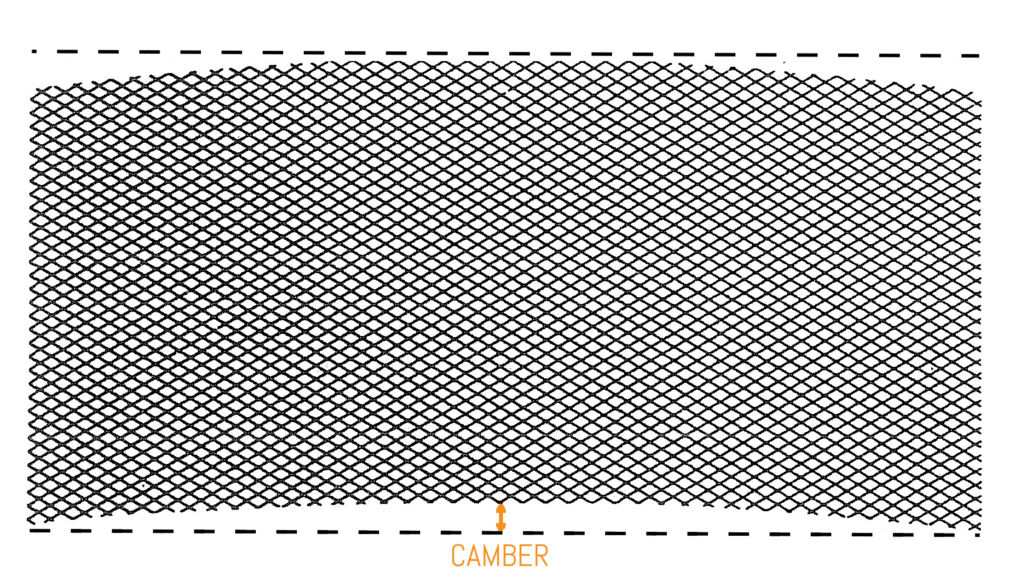

Camber

Camber can be considered ‘bow’ in the sheet. Camber is measured by placing a straight edge along the concave side of the mesh sheet parallel to the Long Way (LW) direction, touching both ends of the sheet. The maximum distance between the edge of the expanded mesh sheet and the straight edge is the camber. The tolerances for camber are:

Raised Expanded Metal – max. 5mm per metre of sheet length

Flattened Expanded Metal – max. 7mm per metre of sheet length

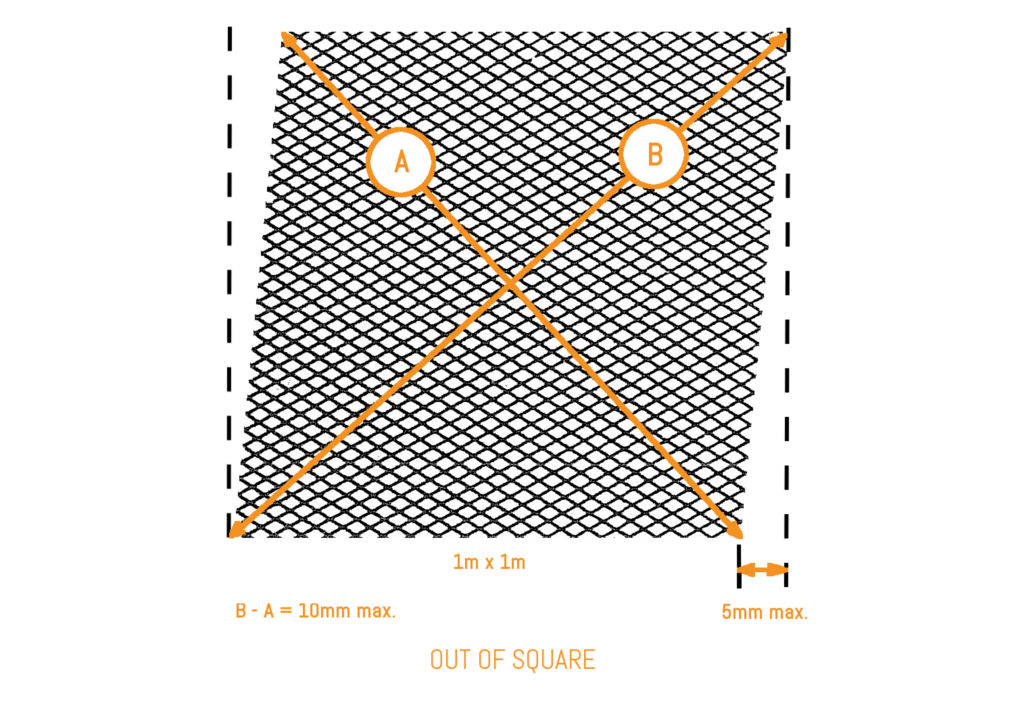

Out of Square

Expanded metal sheets are rarely perfectly square as manufactured and some ‘out of square’ should be expected. The following tolerances apply:

Parallel sides – skewed by max. 5mm per metre of length

Diagonals – max. difference of 10mm between diagonals per square metre